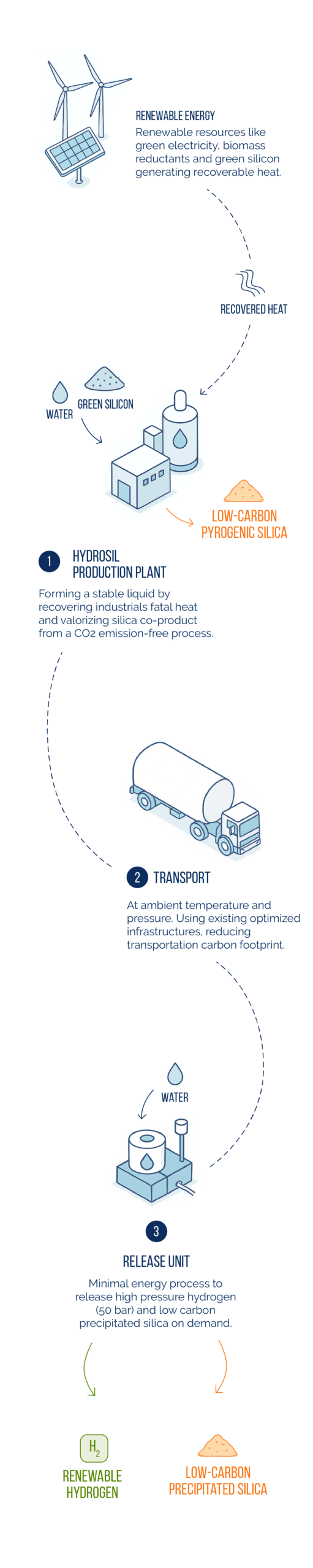

HydroSil is a breakthrough that enables the production, storage, and transportation of

low-carbon silica in a stable liquid form.

HSL Technologies developed a breakthrough patented innovation that enables the production and delivery of decarbonized silica as a liquid form. Once produced, HydroSil can store and transport three times more silica in the same volume than in standard bulk form.

Mainly based on green silicon, water, and hydrogen, HydroSil forms a stable, pumpable liquid that can be used at ambient temperature and pressure using existing liquids infrastructures, eliminating the need for high pressure or cryogenic systems.

Our release reaction allows us to deliver low-carbon silica directly to industrial end-users with minimal energy input and at useful pressure levels. At the same time, we valorize a high purity hydrogen by-product.

By coupling efficient hydrogen logistics with sustainable silica production, HydroSil opens new opportunities for industrial decarbonization of key industries such as elastomers, tires, construction, paints, and coatings.

hydrosil advantages

HydroSil delivers a breakthrough for both silica and hydrogen production and transport, combining optimized density, safe and efficient handling, and seamless infrastructure compatibility. Its low‑carbon, on-demand release process uses abundant, affordable materials, offering scalable, eco-friendly silica and hydrogen valorization to decarbonize key industrials sectors.

Optimized Density

- Simultaneously transports 3× more silica than standard silica in the same volume.

- Liquid storage enables compact, efficient hydrogen transport.

- 7× higher H₂ density than compressed gas at 200 bar.

Infrastructure Compatibility

- No system changes required — fully compatible with existing logistics and storage.

- No compression or cryogenics needed, easily pumpable (100–200 mPa·s).

- Seamless fit within current industrial and transportation networks.

Low-Carbon Process

- ~50% CO₂ reduction with just 5 kWh/kg silica energy input.

- No H₂ used in manufacturing, minimizing production emissions.

- Simultaneous valorization of high-purity hydrogen (15 kt silica = 1 kt H₂).

SAFETY & EFFICIENCY

- Flash point > 60 °C ensures safe handling under ambient conditions.

- Non-toxic, non-flammable, and stable in storage and use.

- Competitive energy input to produce HydroSil.

Cost Competitive,

Affordable Materials

- Made from abundant, low-cost raw materials ensuring scalability.

- Affordable manufacturing with no reliance on rare or high-cost inputs.

- Efficient logistics by combining silica transport and energy storage.

ON DEMAND RELEASE

- Minimal energy input for both production and release.

- Provides high-quality, D-grade H₂ by-product.

- Enables controlled hydrogen generation compatible with renewable sources.

One process, three low-carbon outputs

Low-carbon silica

HydroSil produces two high-value silica products: pyrogenic silica, co-product generated during our production process, and precipitated silica released on-demand directly to end-users. These low-carbon raw materials allows to decarbonize a wide range of industries, including elastomers, tires, food, feed, paints, and coatings. Our silica offers a sustainable, scalable alternative in a growing market demanding eco-friendly, high-performance materials, combining hydrogen innovation with circular value creation.

Minimal energy input

5 kWh for 1 kg of low-carbon silica

industry decarbonation

≈50% of CO2 reduction for end users

high quantities

187 ktons of silica produced each year by one industrial plant

Optimized density

3x more than standard silica

main applications

HydroSil’s innovative silica solutions are designed to enhance functionality, efficiency, and sustainability across a wide range of industrial applications:

Elastomers & Tires

Our silica improves rolling resistance, grip, and durability, supporting safer and more energy-efficient mobility.

Coatings & Paints

It provides superior rheology control, matting effects, and scratch resistance, enabling high-performance finishes and long-lasting protection.

Pharmaceuticals

HydroSil silica serves as a reliable excipient, offering moisture control, flow enhancement, and stability in solid dosage forms.

Agri-Food

Used as an anti-caking and carrier agent, our silica ensures consistent texture, flowability, and shelf-life in food and feed products.

Construction

In building materials, HydroSil silica enhances mechanical strength, durability, and workability in applications such as concrete, sealants, and adhesives—contributing to more resilient and sustainable infrastructure.

hydrogen by-product

After delivering low-carbon silica, we valorize a renewable hydrogen by‑product. It provides a safe, low‑carbon energy source for hubs and industrial applications. Combining high density with on‑demand release, it supports local hydrogen supply and enables the decarbonization of key industries through delocalized, renewable energy solutions that advance the transition to a low‑carbon economy.

main applications

HydroSil delivers versatile hydrogen solutions designed to meet the evolving needs of key sectors such as maritime, rail, and logistics. Its technology ensures the safe, on-demand release of hydrogen, making it particularly well-suited for mobility applications in ports, rail networks, and logistics hubs, where safety and emissions compliance are critical.

For Hydrogen Refueling Stations (HRS), HydroSil simplifies local hydrogen supply, enabling efficient and decentralized distribution to end users. This makes it an ideal solution for supporting the rollout of clean transportation infrastructure.

HydroSil also plays a key role in hydrogen strategic storage, a cornerstone for Europe’s transition to a decarbonized energy system. Additionally, it facilitates the transport of green hydrogen across borders, helping countries achieve their ambitious hydrogen import targets by 2050.

competitive h2 density

7x more than compressed gas

Pumpable & easy to handle

Viscosity 100–200 mPa·s

high quality hydrogen

Spec grade D (ISO standards 14687)

Exothermic reaction

With energy surplus

Safety thresholds

Flash point >60°C

2026

– Release pilot

– Polymerization unit

– Hydrochlorination pilot

2027-2028

– Precipitated silica

Silica powder production pilot

– Permitting & Feed

Middle plant

– Middle release

50 kWe unit

2029-2030

– Middle production plant

Pre-commercial scale

10 t H2 / year

187 t silicas / year

– Industrial release

1 MW unit

2032

– Industrial release

14 x 1 MW unit

– Production plant

10 kt H2 / year

187 kt silicas / year

Our timeline - From the kg to the ton of H2

HydroSil has evolved through successive generations to meet stringent industrial, safety, and sustainability requirements. Early versions addressed key challenges through iterative improvements that reduced corrosion risks, maximized hydrogen yield, and ensured compliance with flammable liquid regulations.

From 2023 onward, we developed new HydroSil formulations at proof-of-concept scale, then scaled demonstrators from 1 kg/day to 5 kg/day to confirm process robustness. In parallel, we worked on enabling instant hydrogen release and efficient silica separation at pilot scale.

By 2026, HSL plans TRL 6 demonstration units for continuous silica release, hydrogen by-product valorization and pre‑commercial HydroSil synthesis, paving the way for industrial deployment. The industrial roadmap targets a first plant around 2029, before scaling toward gigaplants in 2029.